Informations sur les cookies

ACCEPTER

Ce site utilise uniquement des cookies techniques, y compris des cookies tiers, et n’utilise pas de cookies de profilage.

Pour accéder au site, vous devez accepter l'utilisation de cookies en cliquant sur le bouton "Accepter".

Pour plus d'informations sur la manière dont nous utilisons les cookies et sur la façon de les supprimer, consultez notre politique en

matière de cookies.

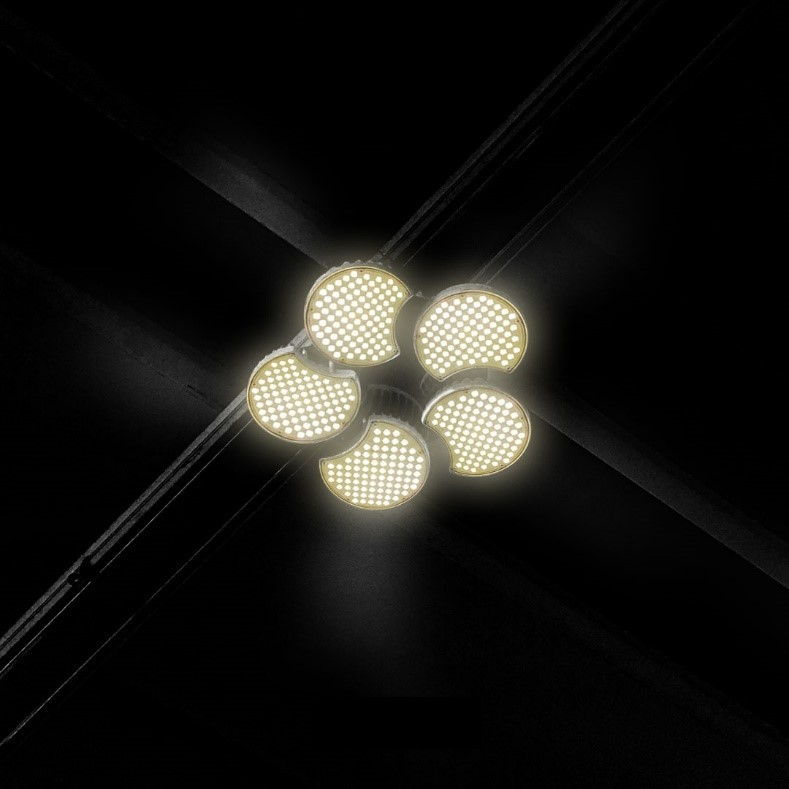

Innovation and precision: how is a lens designed?

Innovation and precision: how is a lens designed?